Vacuum feeding hot melt adhesive into the hot melt applicator is an efficient way to automate and improve the quality and consistency of your hot melt adhesive application.

2 key items should be reviewed to determine if your hot melt adhesive can be vacuumed for auto-feeding your hot melt application equipment.

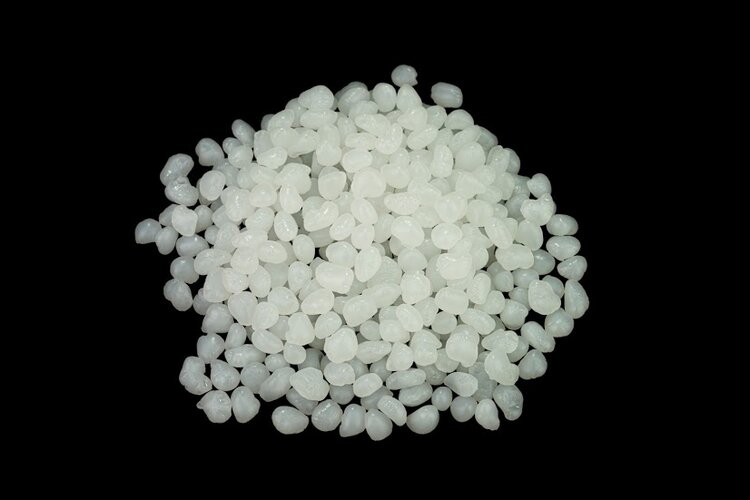

Size of the Solid Hot Melt Form at Room Temperature

Check to see if your current hot melt or a hot melt that comes in small vacuum feed form is available for your application.

Only small forms- the size of large BBs, or small chips – the size of small gum, (Chiclets or smaller), can be vacuum transferred from an auto-feed bin/drum into the hot melt application unit.

The small solid hot melt form must be free flowing at room temperature during shipping and inventory storage.

Some hot melt adhesives come in small from but have residual tack that can form small blocks of adhesive that will not vacuum / auto feed without manually separating the blocks of pellets or chips.

Some small forms can block during shipping and storage.